Jigs and Fixtures in CNC Machining: A Comprehensive Guide

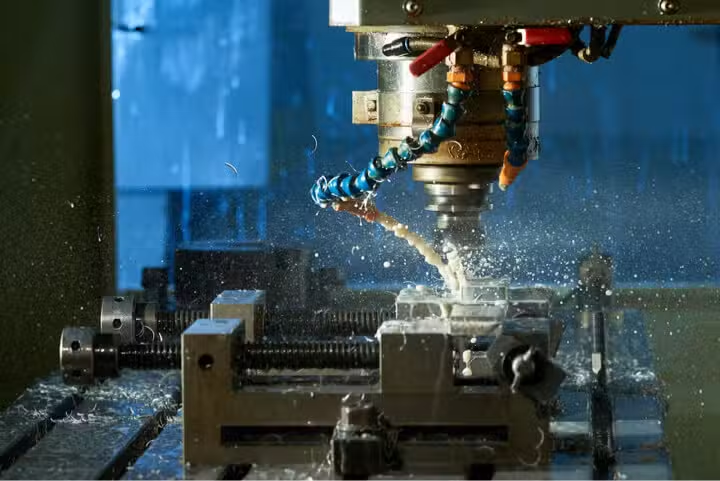

In CNC machining, precision and repeatability are key to quality. Consistent accuracy matters whether you’re making a single part or running large batches. That’s where jigs and fixtures come into play.

These specialized tools help hold, support, or guide the workpiece or cutting tool during machining. They reduce human error, increase efficiency, and ensure each part meets exact specifications.

Jigs typically guide the tool path, while fixtures hold the part steady. Both are essential for minimizing variation and streamlining production. In this guide, you’ll discover the differences, types, uses, and design principles of jigs and fixtures in modern CNC operations.

Introduction to Jigs and Fixtures

What are Jigs and Fixtures?

Jigs and fixtures hold, support, or guide parts during manufacturing processes. While they may sound interchangeable, each plays a unique role:

-

Jigs guide the cutting tool. For example, a drill jig ensures holes are placed precisely and consistently in the exact location on each part.

- Fixtures, on the other hand, do not guide the tool. Their purpose is to hold the workpiece securely in place during machining operations.

These tools help reduce human error, minimize movement, and maintain exact positioning throughout the process. They’re invaluable when you need repeatable, high-quality results.

Jigs and fixtures are often custom-designed for a specific part or operation. Their shape and features vary depending on the part geometry, material, and machining process.

Some may look like clamps, while others resemble complex molds or nested trays. Regardless of appearance, they all serve the same mission—improving precision and streamlining production.

Key Differences Between Jigs and Fixtures

Although jigs and fixtures work toward a common goal—part accuracy—they function differently. Understanding their differences helps you choose the right tool for each job:

-

Jigs guide the tool. They ensure the drill, mill, or other cutting device follows a predetermined path as the tool moves about the jig.

- Fixtures hold the part. They stabilize the workpiece so the machine can perform precise operations without movement. The tool moves independently, controlled entirely by the CNC machine.

To put it simply:

-

A drill jig might include bushings or guides to ensure the bit enters the material at the correct angle and location.

- A fixture like a vise or clamp holds the workpiece still, leaving the CNC program to control the tool path.

Both improve process control, but they tackle it from different angles.

Critical Role in CNC Machining Accuracy and Efficiency

CNC machining is built on precision. But even the most advanced CNC machine can’t perform its best if the part isn’t correctly positioned. Jigs and fixtures solve that issue.

Here’s what they bring to the table:

-

Faster Setup Times: Custom fixtures reduce the need to re-measure or realign a part each time.

-

Better Repeatability: Once a jig or fixture is set up, every part is machined similarly.

- Fewer Mistakes: By eliminating guesswork, they help reduce defects, rework, and wasted material.

The time savings add up fast for high-volume jobs. In prototyping, they help maintain consistency from iteration to iteration.

Operators also benefit. Instead of spending time manually positioning each part, they simply place it in the jig or fixture, secure it, and hit “go.” The result? A smoother, more reliable machining process from start to finish.

Types of Jigs and Fixtures

Every CNC machining operation involves repeatable tasks. That’s where jigs and fixtures shine. Depending on the part, material, and type of operation, different designs serve different purposes. In this section, we’ll walk through the most common types of jigs and fixtures and explain when and why to use each.

Common Jig Types

Jigs are specialized tools that guide the cutting tool to the exact location needed. They’re perfect for jobs that require consistency across multiple parts, especially when drilling or milling in tight tolerances.

Here are some of the most commonly used jig types:

-

Drill Jigs: These jigs ensure holes are drilled at the exact angle and in the correct position every time. They often come with hardened steel bushings to guide the drill bit.

-

Milling Jigs: These are used to guide milling cutters across specific paths. They’re helpful when a CNC machine is unavailable or additional manual milling is needed.

- Template Jigs: These jigs use a flat template with holes or slots that act as a visual and physical guide. They are great for tasks like drilling patterns or profiles.

Advantages of Using Jigs:

-

They maintain high accuracy, especially for repeated operations.

-

Jigs reduce the need for skilled labor, allowing even new operators to produce precision parts.

- They increase output by cutting down on setup and inspection time.

If you’re machining the same part repeatedly, jigs help keep everything fast, accurate, and efficient.

Common Fixture Types

Fixtures hold the workpiece securely in place while the CNC machine cuts. Stability is key. Even the slightest movement can ruin a part or damage a tool.

Here are the most common fixture types found in shops:

-

Vises: These are basic but essential. Used for holding flat parts or blocks in place for most general-purpose machining.

-

Angle Plates: Used when the part must be held at a specific angle—often 90 degrees—to perform precise cuts.

- Modular Fixtures: These systems use interchangeable parts, allowing for fast reconfiguration. They are ideal for shops that handle varied part sizes and shapes.

Fixtures for Complex Workpieces: For curved, rounded, or irregular parts, custom fixtures are often the only way to ensure accuracy. These fixtures are made to match the part’s shape exactly, preventing slippage or shifting during machining. This ensures dimensional accuracy and protects both the part and the cutting tools.

Design Principles for Jigs and Fixtures

Good jigs and fixtures don’t just happen—they’re engineered for performance. Whether you’re building one from scratch or refining an existing setup, understanding a few basic design principles can dramatically improve your machining results. The right design increases stability, boosts accuracy, and extends tool life.

Stability and Rigidity Requirements

The biggest enemy of precision machining is vibration. A fixture or jig that moves—even slightly—can ruin the part, damage the tool, or produce a rough finish. That’s why rigidity is rule number one.

A well-designed jig or fixture must be strong enough to resist all the forces created during machining, including cutting forces, tool pressure, and even machine vibration.

Here’s how to improve rigidity:

-

Use reinforcements and braces to support weaker areas.

-

Avoid unnecessary moving parts, which can introduce play or slack.

- Secure the fixture to the machine bed using bolts or clamps, ensuring nothing shifts during operation.

When your setup is solid, you’ll notice fewer tool marks, better finishes, and more consistent dimensions.

Workpiece Alignment and Clamping Techniques

Next, focus on alignment. Even the best CNC program won’t help if your part isn’t positioned correctly. Every fixture should include features that guide and locate the part accurately.

Key alignment tools include:

-

Locating pins to position the part quickly and precisely.

-

Reference edges to ensure consistent orientation.

-

Soft jaws for grip without damaging delicate parts.

- Hard stops for repeatable placement.

When it comes to clamping, balance is key. Clamps should apply even pressure without bending or crushing the workpiece.

-

Don’t overtighten. This can warp thin parts or create stress.

- Don’t undertighten. This leads to movement and poor cuts.

Well-distributed clamping force helps maintain tolerances and avoids tool chatter.

Material Selection for Jigs and Fixtures

The material of the jig or fixture affects performance, cost, and lifespan. Choosing the right one depends on the job and production volume.

-

Steel: Very strong and wear-resistant. Ideal for heavy-duty or high-volume jobs.

-

Aluminum: Lighter and easier to machine. Great for prototypes and short runs.

- Composites: Used when weight savings or electrical insulation is needed.

Use steel for tough, long-term use. Pick aluminum when you need speed and flexibility. Each has its place, and smart selection ensures your jig or fixture performs its best.

Applications Across Industries

Jigs and fixtures aren’t just helpful—they’re essential across many industries. From mass production to precision engineering, these tools make machining faster, safer, and more accurate. Here’s how they’re used in key sectors.

Automotive Component Machining

In the automotive industry, speed and consistency are everything. Cars are built in high volumes, and every part must meet strict tolerances. Jigs and fixtures help meet these demands without sacrificing quality.

-

Fixtures hold parts like engine blocks, gear housings, and suspension brackets during milling or drilling.

-

Quick-change fixtures reduce downtime between part setups, keeping assembly lines moving.

- Consistent alignment ensures repeatable accuracy, shift after shift.

Jigs are especially valuable in operations like drilling and tapping, where tool guidance matters. Even a tiny mistake can lead to costly rework or safety issues with hundreds or thousands of identical parts produced daily. Jigs dramatically reduce that risk.

Aerospace Precision Parts Manufacturing

Aerospace parts must be light, strong, and incredibly precise. This often means working with difficult materials like titanium, Inconel, and carbon fiber composites. Fixtures used here are specialized:

-

Built for extreme rigidity, even under high stress.

-

Designed to accommodate thermal expansion from machining heat.

- Shaped to support complex, curved geometries.

Jigs guide delicate drilling or cutting operations, particularly in thin-walled or contoured aerospace components. Accuracy is critical when lives are at stake; custom jigs and fixtures make that possible.

Medical Device Prototyping with Fixtures

Medical parts are often tiny and intricate and made in small batches. Fixtures in this field must hold components securely without damaging them.

-

They ensure repeatable positioning for micro-scale machining.

-

Materials must be non-contaminating and bio-compatible.

- Quick-change features help speed up prototyping cycles.

In medical R&D, time matters. A well-designed fixture can distinguish between a successful prototype and a delay.

Advanced Innovations in Jigs and Fixtures

Technology is changing the way we design and use jigs and fixtures. New advancements are making these tools faster, more innovative, and more flexible than ever. Here’s how modern manufacturing is upgrading this essential equipment.

Manufacturing for Fixture Prototyping

CNC Machining:

Good for making strong and precise fixtures, like ones made from aluminum or steel. CNC machines use a computer program to control the machine’s movements, so they can make complicated shapes and very precise parts.

Laser Cutting:

Often used for making fixtures from clear materials like acrylic. Laser cutting can cut very precisely and doesn’t damage the surface of clear materials, so they still look good and clear.

Can make fixtures with complicated shapes that are hard to make with CNC. But 3D-printed parts might not be as precise or strong. For example, PLA (a common 3D-printing material) is not as strong as steel, but you can make it stronger by making the walls thicker.

Smart Fixtures with Integrated Sensors

Smart manufacturing has introduced fixtures that go beyond holding parts. These smart fixtures include embedded sensors that:

-

Monitor clamping pressure and force in real time.

-

Detect unwanted movement or vibration during machining.

- Send data directly to CNC controllers or monitoring systems.

This feedback loop helps prevent part misalignment, tool breakage, or excessive wear. It’s all about reducing errors before they happen.

Quick-Change and Modular Fixtures

Efficiency matters, especially in high-mix, low-volume production. Quick-change fixtures and modular systems allow:

-

Fast part or fixture swaps between jobs.

-

Tool-less locking mechanisms for easier handling.

- Adaptability to multiple part sizes or shapes.

These innovations help reduce setup time, maximize machine uptime, and support lean manufacturing workflows.

Conclusion

Jigs and fixtures play a silent but powerful role in CNC machining. They guide tools, hold workpieces, and streamline processes. Without them, parts would take longer to make and vary in quality. They ensure repeatability, save labor, and reduce the chance of mistakes.

Investing in quality jigs and fixtures pays off whether you’re building automotive parts or medical devices. They’re the backbone of modern CNC shops.

For businesses looking to elevate their manufacturing, ZCprecision offers industry-leading jigs and fixtures tailored to your needs. ZCprecision combines expert engineering with top-grade materials to deliver precision support tools for every CNC project. From custom fixture design to jig fabrication, ZCprecision helps you boost efficiency and reduce production time.